Booster Pump Blog |

A centrifugal water pump is one that moves fluid outward from the center point of rotation. An impeller is the component that does the work, harnessing the power of the motor to ensure the fluids are pumped effectively and efficiently. The impeller generates pressure which is then converted into velocity as the outward movement of the fluid stays confined in what is known as a pump casing. In most cases, the pump casing is a short cylinder with an inlet, known as an eye. How Does the Impeller Work? This is the heart of the centrifugal pump. It lies in the middle of the pumping system and has curved blades known as vanes which rotate. The impeller is immersed in water and the motor which spins the impeller, is what produces the centrifugal force. The impeller is also responsible for the following:

One of the most commonly used type of impeller is an open impeller. These are used in centrifugal water pumps and are very popular. They are used frequently because they:

While many impellers can clog in certain situations, an open impeller rarely does. Can Pump Liquids with Suspended Solids When operating correctly, they can even move fluids with suspended solids in it. Suspended solids can include:

Offers External Adjustment By using the external adjustment, an open impeller can be easy to maintain. By adjusting the open impeller properly, it can extend its life by ensuring the proper clearance is maintained. Adjustments are more common when the open impeller’s parts begin to show signs of wear. The good news, is the adjustments are made outside the casing. There is no need to take the centrifugal pump apart to perform maintenance. This makes adjustments quick and less intrusive than on other impellers. For more info contact booster pump suppliers in uae or call us at +971 4 252 2966

0 Comments

The accurate alignment of a pump is critical for pump performance. Yet nearly half of all damage to rotating equipment comes from misalignment. This usually occurs during installation, but the effects of a misaligned pump occur throughout the pump’s now-shorter lifespan. Issues like:

What is (in)accurate alignment (aka misalignment) of a pump? Misalignment is when the shaft position deviates from the axis rotation when the equipment is running. There are three types of misalignments that can occur: Axial, radial, and angular. If you need to align your pump correctly, you need to consider which tool or methods will be best for your needs. There are 3 common tools, each with their own pros and cons. 3 tools or methods to ensure accurate alignment of your pump: 1. Straight Edge This method relies on visual inspection, which we all know can be faulty. To use straight edge as a method, place a straight edge on the pump and motor coupling, then check to see if the components are aligned. Pros:

This method uses the relative measurement of the centrelines of the two opposing shafts. Two indicator readings across the coupling are taken and these readings are used to mathematically or graphically determine the required adjustments and shimming for each foot of the driver or moveable unit. Pros:

Laser-guided tools consist of two units, each capable of emitting a precise laser beam and detecting a laser beam from the other, plus a hand-held control device. These lasers are used to determine relative shaft positions which are displayed on the handheld device for real-time coupling and feet values during the alignment process. Pros:

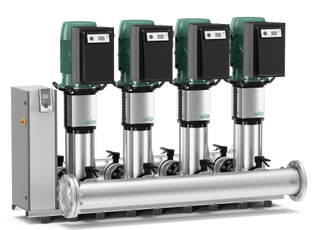

For more info contact booster pump suppliers in uae or call us at +971 4 252 2966  Many facilities shutdown suddenly with little or no notice, whether for emergency or maintenance reasons. This can cause problems when it’s time to start your equipment up again. To make sure you’re ready to start a centrifugal pump, especially after a long shutdown, you need to first check that your spare parts inventory is stocked up and ready. Here’s a step-by-step process of what to do once you’re ready to inspect your pump: Check that the pump can spin freely The most important thing to check is that the pump still spins without issue. Sometimes the pump may contain trapped solids or have mechanical issues from sitting idle – and this is easily detected by checking its spin. To do this, lockout the pump and remove the coupling guard and shaft. Listen for any noise or rubbing. Spin it by hand and listen carefully. If the pump still doesn’t turn, don’t force it – we’ve seen people use a pipe wrench! Rather take it apart and assess. or use a strap wrench instead of a pipe wrench if required. Check the condition of the coupling Now that the coupling guard is off, you might as well assess the overall condition of the coupling. Look for any signs of wear, which could include rubber dust or micro plastics under the coupling. These are usually signs of misalignment, which means you need to align the pump again before starting. Inspect mechanical seals Take a closer look at the seals to see if you can detect any signs of leakage. If you can see any flush water to the seal, make sure that you turn the pump on. Check oil and lubrication levels Lubrication is key to the proper and safe operation of all pumps and drivers (from electric motors to gears, turbines and more). Check your manufacturer’s guide to find lubrication tips for your chosen centrifugal pump. Make sure suction and discharge valves are in the right position Check that suction valves are open. Discharge valves should not be fully open, but 10-15% open. Ensure your centrifugal pump is primed and vented Now that your pump’s suction valves are open, liquid should fill the pump and prime it. Inspect the base Check the base to make sure that all the mounting bolts are tight. There shouldn’t be any soft feet on the pump or motor. Baseplate pads must be level to within .002” per foot and the maximum level from one end to another should not be greater than 1/32”. Now that you’ve checked everything to make sure it’s ready, you can start up the pump. Listen for any strange noise or vibration and check to see that the pump is operating smoothly and that bearings aren’t overheating. That’s it. You’ve now learned how to start a centrifugal pump after shutdown and this handy checklist can be printed out to ensure you do all your checks correctly. For more info contact booster pump suppliers in uae or call us at +971 4 252 2966  A booster pump is designed to increase water pressure or water flow in a hydraulic system. Booster pumps overcome pressure losses caused by long distances or elevation. You can find booster pumps in various applications such as municipal water systems, firefighting operations, and irrigation systems. There are many benefits to using a water pressure booster pump in a hydraulic system. Booster pumps can increase the system’s overall efficiency by ensuring water delivery is at the correct pressure and flow rate. They can also reduce wear and tear on other components and prolong the system’s life. When choosing an industrial water pressure booster pump for your system, it is crucial to consider the following factors: 1. The Required Flow Rate The required flow rate is the most important factor when selecting a booster pump. Flow rate measures how much water is moving through the system over time. Measurement is typically in gallons per minute (gpm) or cubic meters per second (cms). The flow rate will vary depending on the application, but you must determine this before making final decisions. 2. The Required Pressure Pressure is another crucial aspect to consider. Suppose that the target destination for the water is at a higher elevation than the water source. In that case, choose a pump that can generate enough pressure to overcome gravity and deliver the water. 3. The Available Power Source You also need to think about the pump’s power source because some booster pumps use electricity, while others may have a gas engine instead. You need a pump that is compatible with the power source that is available. 4. The Type of Fluid The type of fluid you need to pump is also an important consideration. Some booster pumps are only suitable for pumping clean water; while in contrast, others can handle more viscous fluids such as sewage or sludge. 5. The Overall Size and Weight of the Pump The size and weight of the water pressure booster pump is also important, especially if the pump needs to be portable. Larger pumps will typically be more expensive and require a reliable power source. It is important to select the correct size for the application. 6. The Budget Your budget will also affect the range of options available to you as there are a lot of pumps available on the market. It is crucial to choose one that fits within the budget for the project. Otherwise, you risk overspending not only on the initial cost but also on future maintenance and fuel. Get Your Booster Pumps from a Trusted Source All these factors will help you set up the best commercial water booster pump system for your needs. With so many pump models and types on the market, it’s important to consult an expert. Always get your pumps from a trusted source to ensure that your pumps are of the highest quality. For more info contact booster pump suppliers in uae or call us at +971 4 25 22 966 |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

August 2023

Categories |

Services |

Quick linksAbout us

Products Careers Contact us |

|

RSS Feed

RSS Feed